When Failure Happens,

We Find the Reason.

Advanced Failure Analysis to Detect Root Causes, Prevent Downtime & Save Millions in Asset Losses.

- Identify the exact causes of failure

- Prevent repeated breakdowns

- Ensure compliance & safety standards

- Fast & accurate reporting

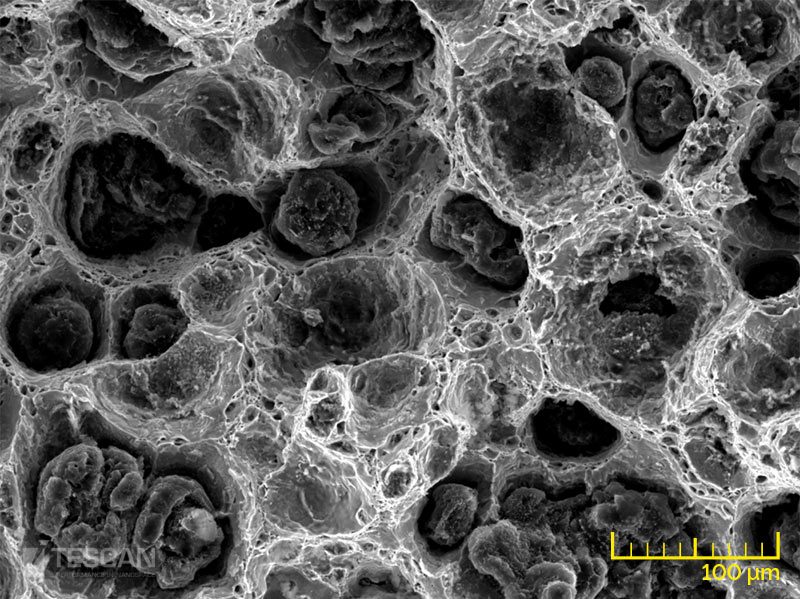

Fracture under SEM

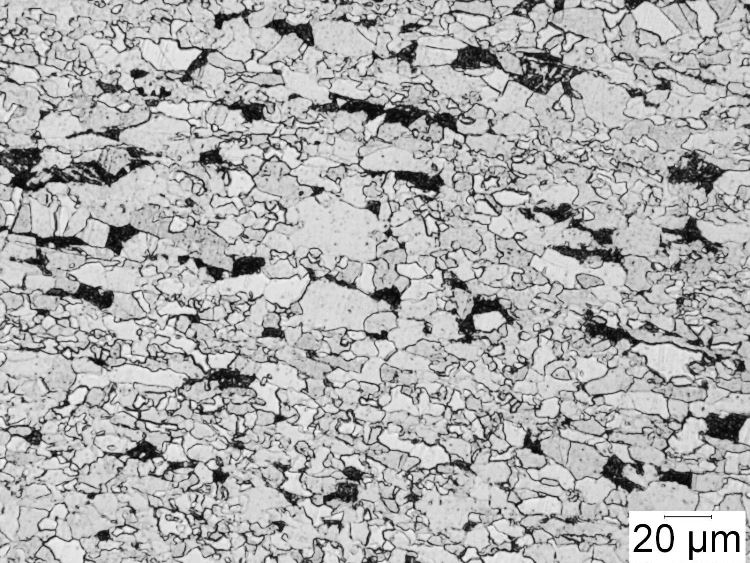

Material Microstructure

Microcellular Fracture Surface

Failure Analysis Services

Our Failure Analysis Services Help You Diagnose Root Causes, Prevent Future Failures and Keep Your Operations Running Safely and Reliably.

- Materials Fracture and Forensic Investigation

- Metallic and Non-Metallic Materials Testing & Characterization

- Plastic & Polymer Failure Investigation

- Composite Materials Failure Analysis

- Stress Corrosion Cracking Investigation

- Root Cause Analysis of Failure Mechanism

- Metallurgical Analysis

- Structural Integrity Analysis

- Design Flaw Investigation

- Material Degradation investigation

- Brittle and Ductile Fracture investigation

- Heat Treatment failureAnalysis

- Fatigue Failure Analysis

Why Components Really Fail

- Incorrect material grade

- Design stress concentrations

- Overloading or misuse

- Poor weld quality

Need urgent analysis?

Our engineers respond Quickly

Expert Failure Analysis with Fast and Accurate Results

- Comprehensive and precise failure analyses: CMH Metlab has the latest technology and highly trained professionals to conduct comprehensive and precise failure analysis services for all types of components.

- Fast and efficient service: CMH Metlab has the capability to quickly assess the damage, identify the cause, and suggest the best corrective action. This helps to reduce downtime and keep operations running smoothly.

- Highly experienced team: CMH Metlab’s team of experienced engineers and technicians have extensive knowledge and experience in all aspects of failure analysis services.

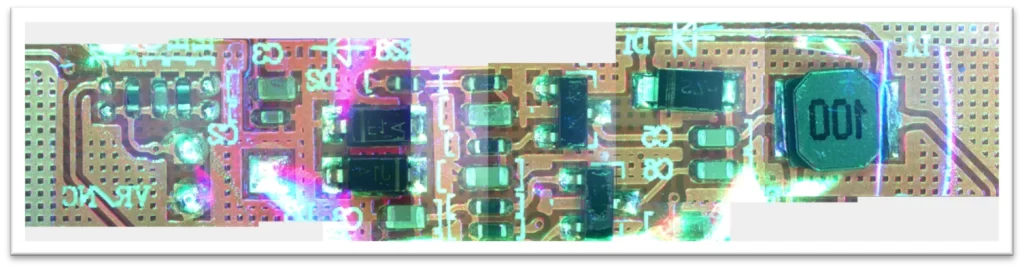

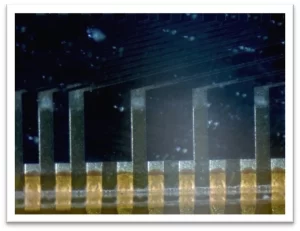

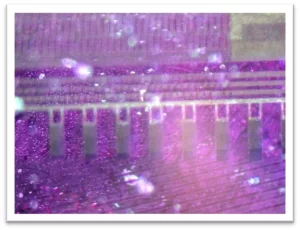

LCD Failures

Chain Failures

Our Approach

- Every project is tailored to your specific situation and industry requirements. Our investigations typically include:

- Fractography & Microscopy: SEM and optical analysis to reveal fracture surfaces and microstructural defects.

- Metallographic Evaluation: Characterization of grain structures, inclusions, and heat treatment history.

- Mechanical Testing: Tensile, hardness, and other mechanical testing to confirm compliance with specifications.

- Chemical & Spectroscopic Analysis: OES, XRF, and FTIR to assess composition and contaminants.

- Corrosion Study & Assessment: Identification of environmental factors contributing to degradation.

- Electronic Component Failure: We can help identify the causes of failure in electronic components and assemblies when related to mechanical damage, overheating, contamination, or corrosion. For example, failures involving cracked solder joints, PCB corrosion, relay fractures, or heat-induced degradation can be effectively investigated.

**Please note: We do not perform root cause analysis of purely electronic or electrical circuitry malfunctions (such as internal semiconductor defects, firmware issues, or design-related electrical failures).

Parts We Commonly Analyze

From tiny fasteners to critical aerospace parts – We analyze them all.

Mechanical Components

- Shafts, axles, crankshafts

- Gears and gearboxes

- Bearings, bushings, springs

- Bolts, studs, nuts, screws, fasteners

- Valves, actuators, hydraulic cylinders

- Welded joints and weldments

Structural Components

- Pressure vessels, tanks

- Pipes, tubes, flanges

- Structural beams, columns

- Heat exchangers

- Castings and forgings

Electrical & Electronic

- Relays and contactors

- Printed Circuit Boards (PCB) – corrosion/mechanicl

- Bus bars, terminals, cable terminations

- Switch housings

Automotive & Aerospace

- Engine and transmission components

- Brake discs, drums

- Turbine blades, rotors

- Landing gear parts, brackets

Industrial Equipment

- Pumps, impellers

- Conveyor parts

- Tooling, dies

- Molds, liners

- Seals, gaskets

Materials & Samples

- Metallic specimens for microstructural analysis

- Coated panels (corrosion testing)

- Polymer/composite fracture samples

- Heat-treated coupons

Why Choose Us?

CMH Metlabs is a full-service chemical testing lab and metallurgy laboratory providing advanced metal analysis, mechanical testing, and NDT testing services for industrial, manufacturing, construction, aerospace, and energy sectors across Canada.

We combine technical expertise, modern instrumentation, and standards-based testing to deliver reliable, defensible results you can trust.

ISO-Accredited Laboratory

Our testing procedures meet internationally recognized standards, ensuring accuracy and consistency in every report.

Experienced Metallurgical Experts

Our team includes seasoned engineers and scientists with decades of combined experience in materials testing and failure analysis.

Client Centric Approach

We go beyond testing by supporting you as a technical partner with accurate results, actionable advice, and long-term assistance focused on your goals.

Precise Results

We understand the importance of timelines, that’s why we deliver accurate results quickly, without compromising quality.

Comprehensive Testing Capabilities

Whether you need metallurgical analysis, non-destructive testing, or comprehensive failure investigation, our lab delivers a full range of services in one integrated facility.

High Tech Laboratory Systems

We invest in the latest analytical tools, including SEM/EDS, optical microscopy, spectrometry, and advanced mechanical testing systems to ensure the highest level of precision and confidence in every result.

Brands That Trust Us

What Our Clients Say!

Trustindex verifies that the original source of the review is Google. Birla Carbon Hamilton worked with CMH for testing their boiler tube . CMH Metlabs issued a report for their testing. The report was good and covered all technical requirements. We will work with them in future.Trustindex verifies that the original source of the review is Google. CMH Metlabs did a number of chemical analysis for us over the last few weeks. The prices are good and the turn-around time was excellent. We needed some clarity on the results from the tests. The technical people at CMH responded quicky and our questions were answered. We discovered a couple of typos in the reports but it did not affect the over all accuracy of the report. We are looking forward to continuing our analyses with CMH.Trustindex verifies that the original source of the review is Google. I highly recommend this company. Their testing is very detailed and thorough.Trustindex verifies that the original source of the review is Google. Submitted metal sample for testing, obtained test results promptly and professionally. Highly Recommended.Trustindex verifies that the original source of the review is Google. The team at CMH Metlabs was very accommodating with our last-minute FTIR and TGA analysis request and turned the testing around in record time (Next business day when the original estimate was 5 working days). Fast and Precise results, very reasonably priced.Trustindex verifies that the original source of the review is Google. Service was prompt and professional. Thank you.Trustindex verifies that the original source of the review is Google. I received timely feedback and reliable results which was all that I wanted.Trustindex verifies that the original source of the review is Google. Very professional, thorough, reliable, and affordable. No need to look furthurTrustindex verifies that the original source of the review is Google. Great team to work with. Atta was very informative and provided useful advice regarding testing methods and protocols to aid with my investigation.Trustindex verifies that the original source of the review is Google. Great service throughout the entire process and detailed results in our final report.